The Textile Without Weaving

Sep 04,2024

In the public’s understanding, traditional fabrics are made through weaving. However, the name "nonwoven fabric" raises questions — is it really not woven?

Nonwoven fabric, also known as "nonwoven," is a type of fabric that does not require weaving or knitting. Unlike traditional textiles, which are formed by weaving threads together, nonwoven fabric is made by bonding fibers directly through physical methods. In terms of manufacturing, nonwoven fabric is produced by directly using polymer chips, short fibers, or filaments to form a fiber web through airflow or mechanical means, which is then reinforced through processes like spunlacing, needling, or thermal bonding, and finally treated to create the fabric.

The nonwoven production process can be broken down into the following steps:

- Fiber carding

- Web formation

- Web consolidation

- Heat treatment

- Final finishing and processing

Based on production methods, nonwoven fabrics can be classified into the following categories:

- Spunlace Nonwoven Fabric: High-pressure water jets are sprayed onto one or more layers of fiber webs, causing the fibers to intertwine and reinforce the web.

- Thermally Bonded Nonwoven Fabric: Fibrous or powdered hot-melt adhesive reinforcement materials are added to the fiber web, which is then heated, melted, and cooled to form a consolidated fabric.

- Airlaid Pulp Nonwoven Fabric: Also known as dust-free paper or dry-laid paper nonwoven fabric, this process uses air-laid technology to convert wood pulp into single fibers, which are then formed into a web and consolidated into fabric through airflow.

- Wetlaid Nonwoven Fabric: In this process, fiber raw materials are placed in a water medium, opened into individual fibers, and mixed. The fiber suspension is then delivered to a web-forming mechanism, where the fibers are consolidated into fabric in a wet state.

- Spunbond Nonwoven Fabric: Polymers are extruded and stretched to form continuous filaments, which are laid into a web and reinforced either by bonding or mechanical means to produce nonwoven fabric.

- Meltblown Nonwoven Fabric: The production process involves polymer feeding, melting, extruding, fiber formation, fiber cooling, web forming, and finally reinforcement into fabric.

- Needlepunched Nonwoven Fabric: A type of dry-laid nonwoven fabric, where the web is reinforced into fabric using mechanical needle-punching.

- Stitchbond Nonwoven Fabric: Another type of dry-laid nonwoven fabric, this process uses knitting loops to reinforce webs, yarn layers, or nonwoven materials (such as plastic films) to form nonwoven fabric.

The fiber raw materials used in nonwoven fabric production are diverse, including cotton, flax, wool, asbestos, fiberglass, viscose (rayon), and synthetic fibers such as nylon, polyester, acrylic, PVC, and vinylon. However, modern nonwoven fabrics no longer primarily rely on cotton fibers, as other fibers like rayon have replaced it.

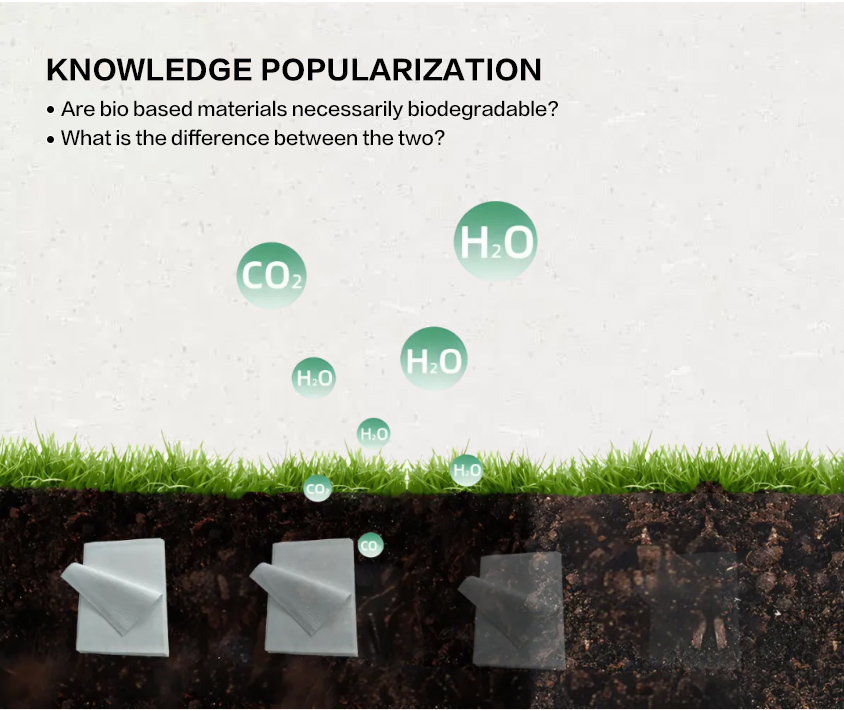

Nonwoven fabric is also recognized as a new type of environmentally friendly material. It has properties such as moisture resistance, breathability, elasticity, light weight, flame resistance, biodegradability, non-toxicity, non-irritation, rich colors, low cost, and recyclability, making it widely applicable.

Applications of Nonwoven Fabric:

Industrial Materials: Due to its high filtration efficiency, insulation, thermal insulation, acid and alkali resistance, and tear resistance, nonwoven fabric is commonly used in products such as filter media, soundproofing materials, electrical insulation, packaging, roofing materials, and abrasives.

Consumer Goods: It can be used in garment linings, curtains, wall coverings, diapers, and travel bags.

Medical and Hygiene Products: It is used in the production of surgical gowns, patient gowns, face masks, sanitary pads, and more.

(Source: Xinhua News)

Latest News

Contact Information

Hangzhou Jeenor industrial Co.,Ltd

Factory Add: Plant Xincheng, Qiantan Area, Jiande District,311602, Hangzhou, China.

Hangzhou Jiekang New Material Co.,Ltd

Office Add: Room#801, Tower D, Tongwen Road No.1795, Xiaoshan District, 311215, Hangzhou, China.