Meeting Industry Standards: A Guide to Choosing the Right Spunlace Nonwoven

|

Understanding Industry Standards for Spunlace Nonwoven Factors to Consider When Choosing Spunlace Nonwoven Practical examples of how spunlace nonwoven can improve product performance |

Introduction

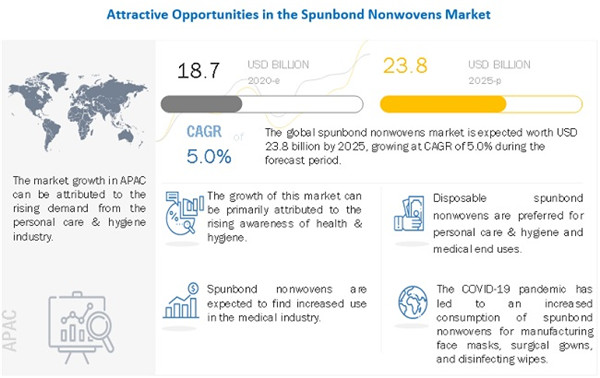

In various industries such as healthcare, automotive, and consumer goods, meeting industry standards is crucial to ensuring product quality, safety, and compliance. When it comes to choosing the right spunlace nonwoven fabric for your specific applications, understanding industry standards is paramount.

Importance of meeting industry standards

Meeting industry standards is essential for several reasons:

1. Quality Assurance: Industry standards provide a benchmark for quality. By following these standards, manufacturers can ensure that their products meet specific quality requirements. Customers can trust that products manufactured to industry standards are reliable and perform as expected.

2. Safety Compliance: Industry standards often include safety requirements that help protect consumers and users. Compliance with these standards ensures that products are safe to use, reducing the risk of accidents or harm.

3. Legal Compliance: Noncompliance with industry standards can result in legal repercussions, including fines, litigation, and damage to a company's reputation. Meeting industry standards helps businesses avoid legal complications and maintain a positive image in the market.

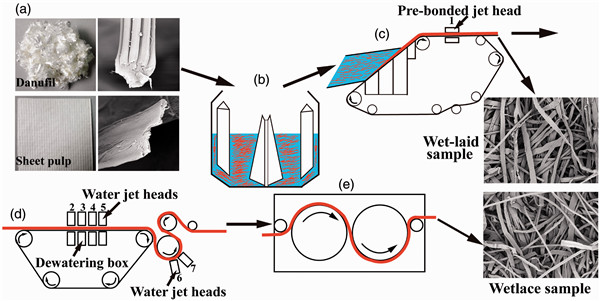

Overview of spunlace nonwoven fabric

Spunlace nonwoven fabric is a versatile material that finds applications in various industries. It is made by mechanically entangling fibers using high-pressure water jets. This process creates a fabric with exceptional strength, softness, and absorbency.

The key advantages of spunlace nonwoven fabric are:

1. High Absorbency: Spunlace nonwoven fabric is known for its excellent liquid absorption properties, making it ideal for wipes, medical dressings, and hygiene products.

2. Softness: The entangled fibers create a fabric with a soft and gentle texture, making it suitable for use in products that come into contact with the skin.

3. Strength and Durability: Despite its softness, spunlace nonwoven fabric exhibits excellent strength and durability, allowing it to withstand rough handling and repeated use.

4. Versatility: Spunlace nonwoven fabric can be produced using a wide range of fibers, including natural and synthetic materials. This versatility allows manufacturers to tailor the fabric's properties to specific applications.

When choosing spunlace nonwoven fabric, it is essential to consider industry standards specific to your application. Look for standards that address factors such as fiber composition, fabric weight, dimensional stability, and performance criteria. Consulting these standards will guide you in selecting a product that meets your requirements and ensures compliance with industry expectations.

In conclusion, meeting industry standards is crucial for businesses in various industries. For those considering spunlace nonwoven fabric, understanding the importance of these standards is vital. By adhering to industry standards, manufacturers ensure product quality, safety, and legal compliance. Spunlace nonwoven fabric offers excellent absorbency, softness, strength, and versatility, making it a popular choice in many applications. Considering industry standards specific to spunlace nonwoven fabric will help you make an informed decision when choosing the right product for your needs.

Understanding Industry Standards for Spunlace Nonwoven

When it comes to choosing the right spunlace nonwoven for your needs, understanding industry standards is crucial. Ensuring that the nonwoven material meets these standards is essential for achieving the desired quality and performance. In this guide, we will explore the key industry standards for spunlace nonwoven and discuss factors to consider when selecting the right product.

Key industry standards for spunlace nonwoven

1. ISO 9073: This International Organization for Standardization (ISO) standard specifies test methods for determining various physical and mechanical properties of nonwoven fabrics, including spunlace nonwoven. These tests evaluate factors such as thickness, density, tensile strength, tear resistance, and abrasion resistance.

2. Cotton-like appearance and hand feel: A high-quality spunlace nonwoven should provide a cotton-like appearance and a soft, luxurious hand feel. This is achieved by ensuring proper fiber selection, uniformity in web formation, and appropriate bonding techniques.

3. Absorbency: Spunlace nonwoven is often used in applications where absorbency is important, such as wipes and medical products. The absorbency of the material should meet the specific requirements of the intended use.

4. Lint-free: In industries such as electronics, automotive, and healthcare, the presence of lint can be detrimental. Spunlace nonwoven used in these applications should be lint-free to avoid any contamination or damage.

Factors to consider when selecting a spunlace nonwoven

1. Purpose and application: Determine the specific purpose and application of the spunlace nonwoven. Different industries may require different properties, such as absorbency, strength, or filtration capabilities. Understanding the intended use will help you identify the most suitable product.

2. Fiber selection: Consider the type of fibers used in the nonwoven fabric. Natural fibers, such as cotton or viscose, offer excellent absorbency and softness, while synthetic fibers, such as polyester or nylon, provide durability and strength.

3. Weight and thickness: Choose a spunlace nonwoven that has the appropriate weight and thickness for your application. Thicker materials may offer better absorbency, while lighter ones may be more suitable for delicate tasks.

4. Sustainability: With increasing environmental concerns, consider the sustainability of the spunlace nonwoven. Look for products made from renewable or recycled materials and those that can be easily recycled or biodegraded after use.

5. Certifications and compliance: Ensure that the spunlace nonwoven meets relevant certifications and industry standards. Look for products that have been tested and approved for specific applications, such as medical or food contact.

By considering these factors and ensuring compliance with industry standards, you can make an informed decision when selecting the right spunlace nonwoven for your needs. It is recommended to consult with suppliers or industry experts to understand the specific requirements of your application and find the most suitable product.

Quality Assurance and Testing

When it comes to choosing the right spunlace nonwoven for your specific needs, you need to ensure that it meets industry standards. Quality assurance and testing play a crucial role in determining the suitability and performance of the nonwoven material. By understanding the quality control measures and testing methods, you can make an informed decision and ensure that you are investing in a product that meets your requirements.

Quality control measures for spunlace nonwoven

Quality control measures for spunlace nonwoven involve various steps to ensure that the product meets the desired standards. Here are some key measures to look out for:

1. Raw material selection: One of the first steps in quality control is selecting the right raw materials. This includes evaluating the fiber type, blend, and purity to ensure consistency and performance.

2. Production process monitoring: It is essential to monitor the production process to ensure that it adheres to specific parameters and guidelines. This includes monitoring factors such as water pressure, temperature, and energy inputs to maintain consistency in the final product.

3. Product testing: Regular testing is conducted on spunlace nonwoven to check for parameters such as tensile strength, elongation, basis weight, and uniformity. These tests help determine the quality and performance of the nonwoven material.

Testing methods to ensure compliance with industry standards

To ensure compliance with industry standards, various testing methods are used to assess the performance and suitability of spunlace nonwoven. Here are some common testing methods that manufacturers employ:

1. Tensile strength testing: This test measures the maximum amount of force a nonwoven material can withstand before breaking. It is crucial for applications that require strength and durability.

2. Basis weight analysis: Basis weight analysis measures the weight of a given area of nonwoven material. It helps determine the density and thickness of the material, ensuring that it meets the required specifications.

3. Absorption capacity testing: Spunlace nonwoven materials are often used in applications where liquid absorption is essential. Testing methods such as the water absorption test help evaluate the material's ability to absorb and retain liquids effectively.

4. Uniformity testing: Uniformity testing ensures that the nonwoven material has consistent properties throughout. This includes parameters such as fiber distribution, thickness, and surface smoothness, which contribute to the overall quality and performance of the nonwoven material.

By using these testing methods and implementing quality control measures, manufacturers can ensure that spunlace nonwoven meets industry standards and performs optimally in various applications.

In conclusion, when choosing the right spunlace nonwoven, it is crucial to consider quality assurance and testing. By understanding the quality control measures and testing methods employed by manufacturers, you can make an informed decision and select a product that meets your specific requirements while also complying with industry standards.

Factors to Consider When Choosing Spunlace Nonwoven

Specific application requirements

When it comes to selecting the right spunlace nonwoven for your needs, it is essential to consider the specific application requirements. Each industry and application may have unique demands that must be met for optimal performance.

1. Strength and durability: If your application requires a nonwoven fabric with high strength and durability, you will need to choose a spunlace nonwoven that can withstand heavy use or stress. This is particularly important for applications in industries such as automotive, healthcare, and agriculture, where the nonwoven will be subjected to harsh conditions.

2. Absorbency: For applications that require absorbency, such as in the healthcare or cleaning industries, it is important to choose a spunlace nonwoven with high absorbency properties. This will ensure effective absorption of liquids, oils, or other substances.

3. Softness: If your application involves direct contact with the skin, such as in baby wipes or facial masks, softness is a crucial factor to consider. Look for a spunlace nonwoven that offers a gentle and comfortable feel without causing irritation or discomfort.

Environmental sustainability considerations

In today's world, environmental sustainability is an important consideration for many businesses. When choosing a spunlace nonwoven, it is essential to take into account its environmental impact.

1. Biodegradability: Opt for spunlace nonwovens that are biodegradable, meaning they can break down naturally and decompose over time. These nonwovens have a lower impact on the environment and contribute to reducing waste.

2. Recyclability: Some spunlace nonwovens can be recycled and used again in different applications. Choosing recyclable nonwovens helps reduce the consumption of raw materials and energy required for manufacturing new products.

3. Renewable resources: Consider spunlace nonwovens made from renewable resources such as plant fibers, bamboo, or recycled materials. These materials have a lower carbon footprint and help conserve natural resources.

4. Production processes: Look for spunlace nonwovens manufactured using environmentally friendly processes that minimize water and energy consumption, reduce emissions, and use eco-friendly chemicals.

By considering these factors and selecting spunlace nonwovens that meet your specific application requirements and environmental sustainability goals, you can make an informed choice that aligns with your business values and contributes to a more sustainable future.

Practical examples of how spunlace nonwoven can improve product performance

Apart from meeting industry standards, spunlace nonwoven offers practical benefits that can significantly improve product performance. Here are some examples:

1. Enhanced Absorbency: Spunlace nonwoven fabrics have a unique structure that allows for superior absorbency. This makes them ideal for applications such as medical wipes, baby wipes, and cleaning wipes. The increased absorbency ensures efficient cleaning and provides a better user experience.

2. Softness and Comfort: Spunlace nonwoven fabrics are known for their softness and luxurious feel. They can be used in various applications such as bedding, upholstery, and clothing to enhance comfort levels. When customers experience the softness of a product, it leaves a lasting impression and increases their satisfaction.

3. Increased Strength and Durability: Spunlace nonwoven fabrics can be engineered to have high tensile strength and resistance to tearing. This makes them suitable for products that require durability, such as automotive interiors, geotextiles, and filtration materials. By using spunlace nonwoven, businesses can ensure their products stand the test of time.

4. Improved Cleanliness and Hygiene: Spunlace nonwoven materials have excellent cleanliness properties, making them ideal for applications in healthcare, beauty, and food industries. They are lint-free, hypoallergenic, and provide a barrier against contamination. By incorporating spunlace nonwoven, businesses can meet stringent hygiene standards, ensuring the safety of their customers.

In conclusion, spunlace nonwoven has proven to be a reliable material for businesses looking to meet industry standards and improve product performance. Through success stories and practical examples, we have seen how this versatile fabric has helped businesses achieve their goals. By choosing the right spunlace nonwoven, companies can enhance their competitiveness, increase customer satisfaction, and deliver products that meet the highest industry standards.