What is Meltblown Fabric & What are its application?

In the ever-evolving landscape of textile innovation, meltblown fabric has emerged as a game-changer, captivating industries with its exceptional properties and wide-ranging applications. This article delves into the intricacies of meltblown fabric, shedding light on its production process and exploring the diverse sectors where it plays a pivotal role.

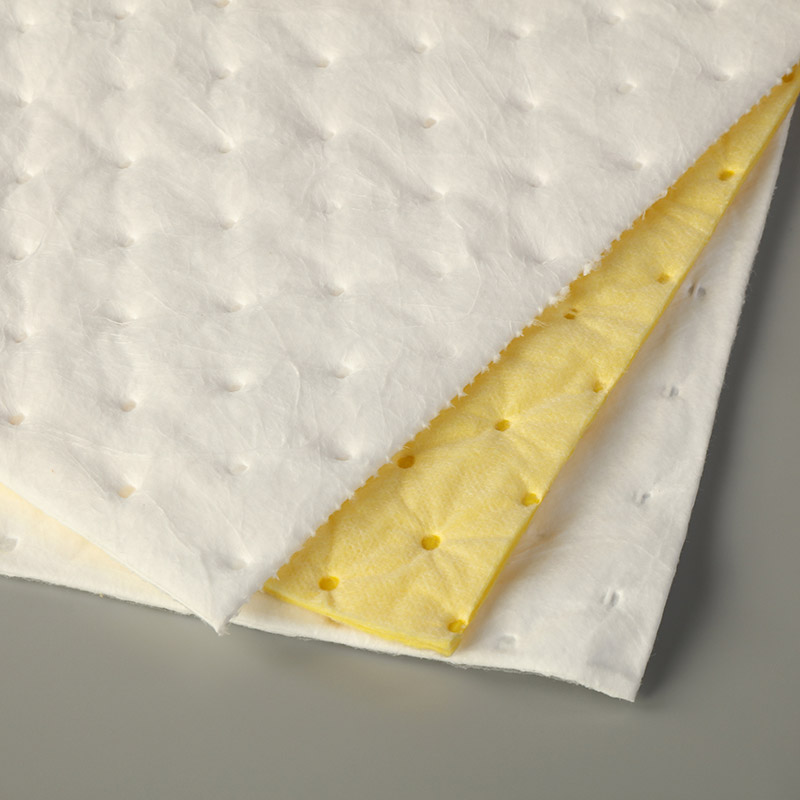

Understanding Meltblown Fabric

JEENOR Meltblown fabric stands as a testament to cutting-edge engineering in the realm of non-woven textiles. This specialized material is produced through a unique manufacturing process known as meltblowing. The process begins with thermoplastic polymers being melted and then extruded through minute nozzles, resulting in ultra-fine microfibers. These microfibers are subsequently collected on a conveyer belt or drum, forming a web-like structure. The outcome is a fabric that boasts remarkable filtration capabilities, making it a preferred choice across various applications.

Exploring Key Advantages:

1) Microfiber Marvel

The standout feature of meltblown fabric lies in its microfiber diameter. The microfibers created through the meltblowing process are incredibly fine, contributing to the fabric's exceptional filtration efficiency. This intricate microstructure enables the fabric to capture even the smallest particles, including bacteria and viruses, making it indispensable in environments demanding high levels of filtration.

2) Filtration Excellence

Meltblown fabric's fine fiber structure translates directly into its high filtration efficiency. The densely woven matrix of microfibers effectively traps particles, contaminants, and pollutants, rendering it indispensable across various sectors, from healthcare to manufacturing.

3) Versatility Embodied

The versatility of meltblown fabric is evident in its extensive array of applications. It serves as a linchpin in the production of surgical masks, N95 respirators, and other personal protective equipment (PPE), where its filtration prowess is of paramount importance. Furthermore, it finds utility in air and liquid filtration systems, oil sorbents, and even within the automotive industry for cabin air filters.

Applications in Various Sectors:

Meltblown fabric finds its niche in an array of industries and applications:

1) Healthcare and Medical

Meltblown fabric is an integral component of the healthcare sector, contributing to the creation of surgical masks, respirators, and medical gowns. Its adeptness at filtering out airborne particles ensures enhanced protection for medical professionals and patients alike.

2) Environmental Protection

In environmental contexts, meltblown fabric finds purpose in air and liquid filtration systems. By capturing pollutants and contaminants from the air and water, it contributes to maintaining clean and healthy environments.

3) Industrial Manufacturing

Within industrial settings, meltblown fabric is a crucial filtration medium. It is employed in the manufacturing of industrial filters, oil sorbents for spill cleanup, and as a component in automotive filtration systems.

4) Hygiene Products

Meltblown fabric's capacity for absorption and liquid barrier functionality makes it a cornerstone in the production of absorbent hygiene products, including diapers, adult incontinence items, and feminine hygiene products.

In conclusion, meltblown fabric stands as a beacon of innovation in the textile landscape. Its remarkable attributes, ranging from microfiber marvel and filtration excellence to its versatile applications, position it as an indispensable material across diverse industries. As technology advances, meltblown fabric is poised to find even more innovative applications, solidifying its role as a versatile and impactful component of modern industrial and everyday life.