OEM and ODM Services: Nonwoven Fabric in Automotive Cleaning

Introduction to OEM and ODM Services for Nonwoven Fabric in Automotive Cleaning

Overview of OEM and ODM services in the automotive industry

Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services play a crucial role in the automotive industry. OEM services involve the production of parts or components according to the specifications provided by the vehicle manufacturer. On the other hand, ODM services focus on designing and manufacturing products based on a specific design provided by the client. These services are widely used in the automotive sector to meet the various needs and requirements of vehicle manufacturers and suppliers.

Benefits of using nonwoven fabric in automotive cleaning

Nonwoven fabric is a versatile material that offers several advantages in automotive cleaning applications. It is made by mechanically or chemically bonding fibers together, providing enhanced strength and durability. Some of the key benefits of using nonwoven fabric in automotive cleaning include:

• Absorbency: Nonwoven fabric has excellent absorption properties, making it ideal for soaking up spills, liquids, and contaminants from various surfaces. This enables efficient cleaning and drying of the vehicle.

• Gentle on surfaces: Nonwoven fabric is soft and non-abrasive, making it safe to use on delicate surfaces such as paint, glass, and upholstery. It helps prevent scratches and damage during cleaning, ensuring the car's aesthetics are maintained.

• Lint-free cleaning: Nonwoven fabric is designed to be lint-free, preventing the transfer of loose fibers onto the cleaned surfaces. This ensures a clean and professional finish without any residual particles.

• Chemical resistance: Nonwoven fabric is resistant to a wide range of chemicals, including detergents, solvents, and cleaning agents. This allows for effective use of cleaning solutions without compromising the integrity of the fabric.

• Cost-effective: Nonwoven fabric is relatively inexpensive compared to traditional cleaning materials, such as cotton or microfiber. Its cost-effectiveness makes it a preferred choice for automotive cleaning applications.

• Versatility: Nonwoven fabric can be easily tailored to specific requirements, such as size, thickness, and texture, allowing for customization based on the cleaning needs. It can be used for various cleaning tasks, including wiping, polishing, and dusting.

In summary, OEM and ODM services are essential in the automotive industry to meet the demands of vehicle manufacturers and suppliers. Nonwoven fabric offers numerous benefits in automotive cleaning, including high absorbency, gentleness on surfaces, lint-free cleaning, chemical resistance, cost-effectiveness, and versatility. These advantages make nonwoven fabric an ideal choice for automotive cleaning applications.

Key Considerations for Choosing the Right OEM and ODM Supplier

Understanding the specific requirements for automotive cleaning nonwoven fabric

Nonwoven fabric plays a crucial role in automotive cleaning, offering several advantages such as absorbency, gentle surface cleaning, lint-free properties, chemical resistance, cost-effectiveness, and versatility. When choosing an OEM and ODM supplier for nonwoven fabric in automotive cleaning, there are some key considerations to keep in mind.

Factors to consider when selecting an OEM and ODM supplier

1. Experience and expertise: Look for suppliers with a proven track record in the automotive industry. They should have extensive experience in manufacturing nonwoven fabric for automotive cleaning and a deep understanding of the specific requirements and regulations.

2. Quality assurance: Ensure that the supplier has a robust quality assurance system in place to ensure consistency and reliability in the production of nonwoven fabric. This includes strict control of raw materials, manufacturing processes, and thorough testing of the final products.

3. Customization capabilities: Consider the supplier's ability to tailor the nonwoven fabric to specific requirements, such as size, thickness, and texture. This allows for customization based on the cleaning needs of different automotive surfaces.

4. Production capacity and efficiency: Assess the supplier's production capacity and efficiency to meet the demand of automotive manufacturers and suppliers. They should have sufficient resources and capabilities to deliver nonwoven fabric in a timely manner without compromising on quality.

5. Cost-effectiveness: Evaluate the supplier's pricing structure to ensure that their nonwoven fabric offers good value for money. While cost should not be the sole determining factor, it is essential to find a supplier that offers competitive pricing without compromising on quality.

6. Technological capabilities: Consider the supplier's technological capabilities, such as advanced equipment and processes that enhance the quality and performance of the nonwoven fabric. This includes capabilities for surface treatments, coatings, and anti-static properties.

7. Environmental sustainability: Look for suppliers that prioritize environmental sustainability by implementing green practices in their operations. This may include using recycled materials, reducing waste, and minimizing energy consumption.

8. Communication and support: Evaluate the supplier's communication channels and support services. They should have a responsive and proactive customer service team that can address any queries or concerns promptly.

By considering these key factors, automotive manufacturers and suppliers can choose the right OEM and ODM supplier for nonwoven fabric in automotive cleaning. This ensures the availability of high-quality, customized, and cost-effective nonwoven fabric that meets the specific requirements of automotive cleaning applications.

Nonwoven Fabric Manufacturing Process for Automotive Cleaning

Overview of the nonwoven fabric manufacturing process

The manufacturing process of nonwoven fabric for automotive cleaning involves several steps to create a material that meets the specific requirements of this application. The process generally includes the following steps:

• 1. Fiber preparation: This step involves the selection and preparation of fibers that will be used as raw material for the nonwoven fabric. The fibers can be natural (such as cotton or jute) or synthetic (such as polyester or polypropylene).

• 2. Web formation: The fibers are then arranged in a web-like structure through various techniques like carding, air-laying, or wet-laying. This forms the basic structure of the nonwoven fabric.

• 3. Bonding: To give the nonwoven fabric strength and stability, the fibers are bonded together using different methods such as thermal bonding, chemical bonding, or mechanical bonding. These bonding methods help to create a fabric that is durable and resistant to tearing.

• 4. Finishing: After bonding, the nonwoven fabric may undergo additional processes like calendering, dyeing, or coating to improve its appearance, performance, or functionality. These finishing processes can enhance attributes like water repellency, UV resistance, or antimicrobial properties.

• 5. Inspection and testing: Before the final nonwoven fabric is packaged and sent to the customers, it undergoes rigorous inspection and testing to ensure it meets the required specifications and quality standards.

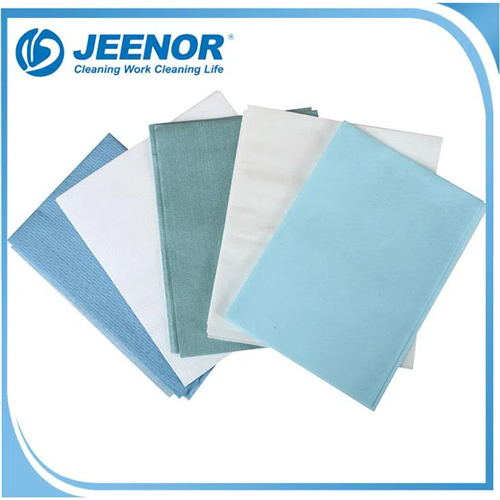

Types of nonwoven fabric used in automotive cleaning

There are different types of nonwoven fabrics used in automotive cleaning, each with its unique characteristics and benefits. Some common types include:

| Type of Nonwoven Fabric | Characteristics | Benefits |

| Spunlaced Nonwoven Fabric | Soft, strong, and highly absorbent | Effective for cleaning surfaces without leaving lint or residue |

| Meltblown Nonwoven Fabric | Thin, fine fibers with high filtration efficiency | Ideal for applications requiring filtration or barrier properties |

| Needle-punched Nonwoven Fabric | Dense and durable with good dimensional stability | Suitable for heavy-duty cleaning tasks and extended use |

Understanding the nonwoven fabric manufacturing process and the different types available can help automotive manufacturers and suppliers make informed decisions when selecting the right fabric for their cleaning applications.

Customization Options for Nonwoven Fabric in Automotive Cleaning

Tailoring nonwoven fabric to meet specific automotive cleaning needs

When it comes to automotive cleaning, it's important to have nonwoven fabric that is tailored to meet the specific cleaning needs of the industry. By customizing the fabric, automotive manufacturers and suppliers can ensure that it delivers optimum performance and meets their requirements. Some ways to customize nonwoven fabric for automotive cleaning include:

• Weight and thickness: Nonwoven fabric can be customized to have different weights and thicknesses, allowing it to be used for various cleaning tasks. Heavier fabrics are suitable for heavy-duty cleaning, while lighter fabrics may be used for gentler cleaning applications.

• Absorption capacity: The absorbency of nonwoven fabric can be adjusted to meet specific cleaning needs. This is crucial in ensuring effective and efficient cleaning, especially when dealing with spills or liquid messes in the automotive industry.

• Surface texture: The texture of nonwoven fabric can be customized to provide the desired level of scrubbing or polishing effect. This allows for better cleaning of different surfaces, such as glass, metal, or upholstery.

• Chemical compatibility: Nonwoven fabric can be customized to be compatible with various cleaning chemicals used in the automotive industry. This ensures that the fabric performs optimally without being damaged or affecting the efficiency of the cleaning agents.

• Color and design: Nonwoven fabric can be customized to have different colors and designs. This allows automotive manufacturers and suppliers to align the fabric with their branding or aesthetic preferences.

Different customization options available from OEM and ODM suppliers

When it comes to customizing nonwoven fabric for automotive cleaning, OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) suppliers offer different customization options. Here's a comparison:

| Customization Options | OEM Suppliers | ODM Suppliers |

| Material selection | Provide a wide range of materials for fabric customization | Offer preselected materials for customization |

| Design flexibility | Allow for more design flexibility based on specific requirements | Offer pre-designed options for customization |

| Production volume | Suitable for large-scale production | Suitable for small to medium-scale production |

| Lead time | Longer lead time due to extensive customization | Shorter lead time due to preselected options |

| Cost | Higher cost due to personalized customization | Lower cost due to pre-existing options |

Understanding the customization options available from OEM and ODM suppliers can help automotive manufacturers and suppliers choose the most suitable option based on their requirements, budget, and production volume.

Advantages of Using Nonwoven Fabric in Automotive Cleaning

Efficiency and effectiveness of nonwoven fabric in automotive cleaning

Nonwoven fabric offers several advantages when it comes to automotive cleaning. Its customization options allow it to meet specific cleaning needs, ensuring optimum performance and efficiency. Here are some of the key advantages:

• Versatility: Nonwoven fabric can be tailored to have different weights and thicknesses, making it suitable for various cleaning tasks. Whether it's heavy-duty cleaning or gentle wiping, nonwoven fabric can be customized to meet the specific requirements of the automotive industry.

• Enhanced absorbency: The absorbency of nonwoven fabric can be adjusted to effectively deal with spills and liquid messes in automotive cleaning. This ensures efficient and thorough cleaning, minimizing the risk of stains or residue on surfaces.

• Improved surface cleaning: Nonwoven fabric's surface texture can be customized to provide the desired level of scrubbing or polishing effect. This allows for better cleaning of different surfaces such as glass, metal, or upholstery, ensuring a pristine finish.

• Chemical compatibility: Nonwoven fabric can be customized to be compatible with various cleaning chemicals used in the automotive industry. This ensures optimal performance of both the fabric and the cleaning agents, without any damage or reduction in effectiveness.

• Aesthetic value: Nonwoven fabric can be customized with different colors and designs, allowing automotive manufacturers and suppliers to align the fabric with their branding or aesthetic preferences. This adds a visual appeal to the cleaning process and contributes to the overall branding of the automotive products.

Benefits of nonwoven fabric over traditional materials

Compared to traditional cleaning materials, nonwoven fabric offers several benefits that make it a preferred choice for automotive cleaning. These include:

• Better cleaning performance: Nonwoven fabric's customized weight, texture, and absorbency make it more effective in removing dirt, grime, and stains from automotive surfaces. It provides a superior cleaning experience compared to traditional materials like cotton rags or towels.

• Time and cost efficiency: Nonwoven fabric's customization options allow for the efficient completion of cleaning tasks, reducing the time required. Its durability and longevity also make it a cost-effective choice in the long run, as it can be used for multiple cleaning applications without compromising its effectiveness.

• Hygiene and safety: Nonwoven fabric is designed to be hygienic and safe for automotive cleaning. It is often made using antibacterial or antimicrobial materials, ensuring a clean and sanitized environment in automotive interiors.

• Environmental sustainability: Nonwoven fabric can be produced using recycled materials, reducing waste and promoting environmental sustainability. Its long lifespan and recyclability further contribute to a greener approach to automotive cleaning.

Overall, nonwoven fabric offers numerous advantages in automotive cleaning, from its customizable features to its superior cleaning performance and sustainability. By opting for nonwoven fabric, automotive manufacturers and suppliers can achieve efficient and effective cleaning results while meeting their specific needs and requirements.

Quality Control and Assurance for Nonwoven Fabric in Automotive Cleaning

Ensuring the quality and durability of nonwoven fabric products

Nonwoven fabric is widely used in automotive cleaning due to its various advantages. However, it is essential to maintain strict quality control measures to ensure that the fabric meets the required standards. Here are some key factors that contribute to the quality and durability of nonwoven fabric in automotive cleaning:

• Raw material selection: High-quality raw materials are crucial for producing nonwoven fabric that is durable and effective in cleaning. Manufacturers carefully select the materials to ensure they meet the desired specifications and performance requirements.

• Manufacturing process: The manufacturing process plays a vital role in determining the quality of nonwoven fabric. Strict control measures are implemented to ensure consistency in the fabrication process, including fiber formation, web formation, and bonding techniques. This ensures that the fabric maintains its integrity and can withstand rigorous use.

• Testing and quality checks: Regular testing and quality checks are conducted throughout the production process to identify any defects or inconsistencies. This includes testing the fabric's absorbency, surface texture, chemical compatibility, and color integrity. By conducting these tests, manufacturers can identify and rectify any issues early on, ensuring the final product meets the required standards.

Quality control measures implemented by OEM and ODM suppliers

Original Equipment Manufacturers (OEM) and Original Design Manufacturers (ODM) in the automotive industry also play a crucial role in maintaining the quality and durability of nonwoven fabric used in automotive cleaning. Here are some of the quality control measures implemented by these suppliers:

By implementing these quality control measures, both manufacturers and suppliers can ensure that nonwoven fabric used in automotive cleaning meets the required standards for efficiency, durability, and safety. This helps maintain the reputation of the automotive industry and delivers high-quality cleaning results for customers.

Conclusion

Summary of the benefits and considerations of using OEM and ODM services for nonwoven fabric in automotive cleaning

Using OEM and ODM services for nonwoven fabric in automotive cleaning offers several benefits, including:

• Access to high-quality raw materials that meet desired specifications

• Consistency in manufacturing processes, ensuring fabric integrity and durability

• Regular testing and quality checks to identify and rectify any issues

• Compliance with industry standards and regulations, ensuring safety and sustainability of the products

However, there are also considerations to keep in mind:

• OEM and ODM services may come at a higher cost compared to non-specialized suppliers

• Regular audits and performance testing may require additional resources and time

Future trends and developments in the industry

In the future, advancements in nonwoven fabric technology and manufacturing processes are expected. These advancements may result in improved cleaning efficiency, even more durable fabric, and enhanced sustainability. Market demand for eco-friendly fabrics and increased emphasis on recycling and waste reduction are likely to shape the future trends in the industry.

Overall, ensuring quality control and assurance for nonwoven fabric in automotive cleaning is crucial to maintain the industry's reputation and deliver high-quality cleaning results for customers. By working closely with OEM and ODM suppliers, manufacturers can meet the required standards and contribute to the continuous improvement of the industry.