Guide to Selecting Spunlace Medical Fabrics: Ensuring Superior Performance and Hygiene Standards

|

Understanding the Importance of Spunlace Medical Fabrics |

Understanding the Importance of Spunlace Medical Fabrics

When it comes to the healthcare industry, ensuring superior performance and maintaining high hygiene standards is of utmost importance. One crucial aspect of achieving this is the selection of the right medical fabrics, and among them, spunlace fabrics have gained significant recognition.

Why are Spunlace Medical Fabrics Important?

Spunlace medical fabrics offer a range of benefits that make them indispensable in various healthcare settings. Here are some key reasons why they are important:

-

Superior Performance: Spunlace fabrics are known for their excellent strength, durability, and resistance to tearing. These qualities make them suitable for demanding applications in healthcare, such as wound dressings, surgical gowns, and drapes.

-

High Absorbency: Medical procedures often involve dealing with fluids, and spunlace fabrics excel in absorbency. They can quickly absorb and retain both liquid and solid substances, ensuring a clean and dry environment.

-

Softness and Comfort: Patient comfort is paramount in healthcare, and spunlace fabrics offer a soft and gentle touch against the skin. They provide a comfortable experience for patients during procedures or while wearing medical garments.

-

Hygiene and Infection Control: Maintaining cleanliness and preventing the spread of infections is critical in healthcare settings. Spunlace fabrics have excellent cleanliness and hygiene properties, making them suitable for use as sterile packaging, wipes, and other disposable medical products.

Guidelines for Selecting Spunlace Medical Fabrics

Selecting the right spunlace medical fabric requires careful consideration of various factors. Here are some guidelines to follow:

-

Performance Requirements: Identify the specific performance requirements for your application. Consider factors such as strength, absorbency, barrier properties, and compatibility with sterilization processes.

-

Material Composition: Understand the different material compositions available and their suitability for your desired application. Consider factors such as comfort, hypoallergenic properties, and compatibility with other materials.

-

Regulatory Compliance: Ensure that the spunlace fabric complies with relevant industry regulations and standards, such as ISO and FDA guidelines. This ensures that the fabric meets the necessary safety and quality requirements.

-

Supplier Reputation: Work with a reputable supplier who has a proven track record in providing high-quality medical fabrics. Look for suppliers with certifications and experience in the healthcare industry.

By following these guidelines and understanding the importance of spunlace medical fabrics, healthcare facilities can ensure superior performance and maintain the highest hygiene standards. Investing in the right medical fabrics is crucial for providing the best care possible to patients and creating a safe and clean environment.

Essential Factors to Consider

When it comes to selecting spunlace medical fabrics, there are several essential factors that healthcare facilities should consider. Making the right choice is crucial for ensuring superior performance and maintaining high hygiene standards. Here are two key factors to keep in mind:

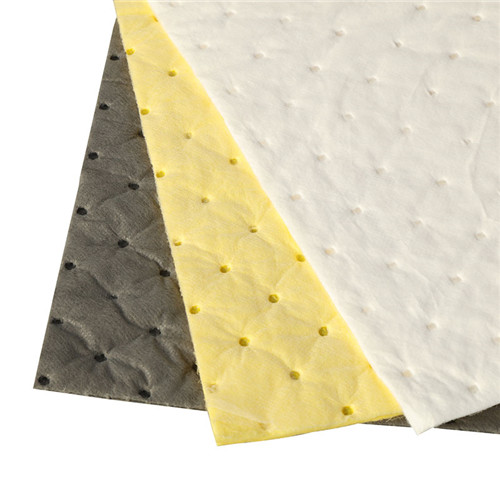

1. Fabric Composition

The composition of the fabric is a critical factor to consider when choosing spunlace medical fabrics. Different materials offer varying levels of comfort, durability, and compatibility with other materials. It is important to select a fabric that provides the necessary properties for your specific application.

For instance, if the fabric is intended for wound dressings, surgical gowns, or drapes, it should have excellent strength and durability to withstand demanding applications. On the other hand, if the fabric will be used for patient garments, comfort and softness against the skin are essential.

Understanding the different material compositions available and their suitability for the desired application is crucial. Consider factors such as hypoallergenic properties, comfort, and compatibility with other materials or sterilization processes.

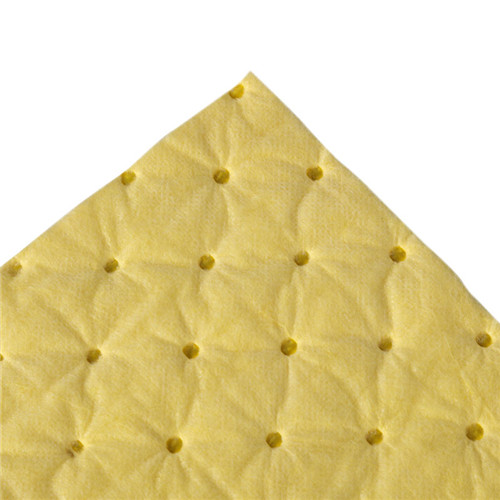

2. Antimicrobial Properties

Maintaining hygiene and preventing the spread of infections is of utmost importance in healthcare settings. Therefore, selecting spunlace medical fabrics with antimicrobial properties is highly recommended.

Fabrics with antimicrobial properties can help inhibit the growth of bacteria, viruses, and other harmful microorganisms. This feature is especially important for products such as sterile packaging, wipes, and other disposable medical items.

By incorporating antimicrobial properties into spunlace fabrics, healthcare facilities can enhance their infection control measures and reduce the risk of cross-contamination.

In conclusion, when selecting spunlace medical fabrics, it is essential to consider factors such as fabric composition and antimicrobial properties. By carefully evaluating these factors, healthcare facilities can ensure superior performance, patient comfort, and the highest hygiene standards. Investing in the right medical fabrics is a crucial step in providing the best care possible to patients and creating a safe and clean environment in healthcare settings.

Performance Considerations

When it comes to selecting spunlace medical fabrics, healthcare facilities must consider several essential factors to ensure superior performance and maintain high hygiene standards. Making the right choice is crucial in providing the best care possible to patients. Here are two key factors to keep in mind:

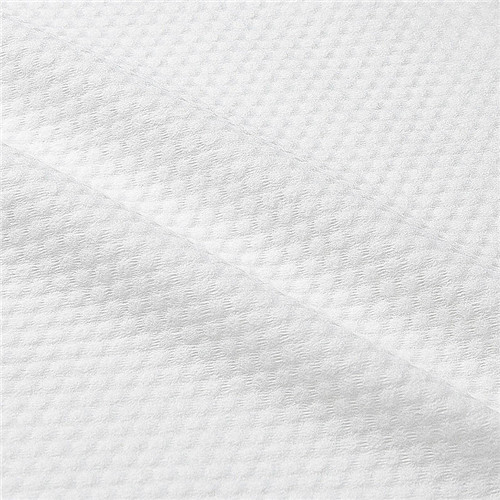

1. Tensile Strength and Tear Resistance

The tensile strength and tear resistance of the fabric are critical considerations when choosing spunlace medical fabrics. These factors determine the fabric's ability to withstand demanding applications. For wound dressings, surgical gowns, or drapes, the fabric should have excellent strength and durability. It should be able to withstand rigorous use without tearing or losing its protective properties.

On the other hand, for patient garments or bedding materials, comfort and softness against the skin are paramount. The fabric should be gentle and non-irritating, providing a comfortable experience for patients while maintaining its structural integrity.

Understanding the different fabric compositions and their suitability for specific applications is crucial in selecting the right fabric. Consider factors such as hypoallergenic properties, compatibility with other materials, and resistance to sterilization processes when evaluating the tensile strength and tear resistance of spunlace medical fabrics.

2. Fluid Absorption Capacity

Maintaining hygiene and preventing the spread of infections are priorities in healthcare settings. Therefore, selecting spunlace medical fabrics with excellent fluid absorption capacity is highly recommended.

Medical procedures often involve the use of fluids and require materials that can absorb and retain them effectively. Spunlace medical fabrics with high fluid absorption capacity can help prevent the contamination of surroundings, protect healthcare professionals, and provide a clean and safe environment.

By carefully evaluating the fluid absorption capacity of spunlace medical fabrics, healthcare facilities can ensure superior performance and meet their hygiene standards effectively.

In conclusion, when selecting spunlace medical fabrics, healthcare facilities should consider factors like tensile strength, tear resistance, and fluid absorption capacity. These factors determine the fabric's durability, comfort, and effectiveness in maintaining high hygiene standards. By investing in the right medical fabrics, healthcare facilities can provide the best care possible to patients and create a safe and clean environment in healthcare settings.

Hygiene Standards

When it comes to selecting spunlace medical fabrics, healthcare facilities must prioritize superior performance and maintain high hygiene standards. Making the right choice is crucial in providing the best care possible to patients. Here are two key factors to keep in mind:

1. Sterilization Compatibility

Ensuring the compatibility of spunlace medical fabrics with sterilization processes is crucial in maintaining hygiene standards. Medical fabrics are commonly exposed to various sterilization methods to eliminate potential pathogens and reduce the risk of infections.

Healthcare facilities should consider fabrics that can withstand sterilization processes such as autoclaving, ethylene oxide (EO) sterilization, or gamma irradiation without compromising their physical properties or performance. Understanding the fabric's resistance to these sterilization methods is essential to ensure that the fabric remains intact and retains its integrity after each sterilization cycle.

Additionally, it is important to consider the hypoallergenic properties of spunlace medical fabrics. Some patients may have sensitivities or allergies to certain materials, and using hypoallergenic fabrics can minimize the risk of adverse reactions.

2. Barrier Effectiveness

Maintaining a clean and safe environment is crucial in healthcare settings, and selecting spunlace medical fabrics with excellent barrier effectiveness can contribute to achieving this goal. The fabric should act as a protective barrier to prevent the spread of infections and maintain a hygienic environment.

The barrier effectiveness of spunlace medical fabrics is determined by factors such as fluid resistance, particulate filtration, and bacterial filtration efficiency. Fabrics with high fluid resistance can effectively repel liquids and prevent contamination, while fabrics with efficient filtration properties can help trap airborne particles and bacteria.

Healthcare facilities should carefully evaluate and select spunlace medical fabrics that meet the required barrier effectiveness standards. This will not only protect healthcare professionals but also contribute to the overall safety and well-being of patients.

In conclusion, healthcare facilities must consider sterilization compatibility and barrier effectiveness when selecting spunlace medical fabrics. Ensuring that the fabrics can withstand sterilization processes and provide an effective barrier against fluids and contaminants is crucial in maintaining superior performance and hygiene standards. By choosing the right spunlace medical fabrics, healthcare facilities can provide the best care possible to patients and create a safe and clean environment in healthcare settings.

Specialized Applications

When it comes to selecting spunlace medical fabrics, healthcare facilities must consider specialized applications such as surgical gowns and wound dressings. These applications have unique requirements that need to be met to ensure superior performance and hygiene standards.

1. Surgical Gowns

Surgical gowns are essential for maintaining a sterile environment during surgical procedures. When choosing spunlace medical fabrics for surgical gowns, healthcare facilities should prioritize the following factors:

-

Fluid Resistance: Surgical gowns should provide a high level of fluid resistance to protect both the healthcare professionals and the patients from potential contamination. Fabrics with excellent fluid repellency properties can help prevent the penetration of blood, bodily fluids, and other contaminants.

-

Breathability: While maintaining fluid resistance, surgical gowns should also allow for proper airflow and breathability to ensure comfort for the healthcare professionals. Fabrics with good moisture vapor transmission properties can help enhance the overall comfort level during long surgical procedures.

-

Barrier Effectiveness: Surgical gowns should act as an effective barrier against bacteria and other pathogens. Fabrics with high bacterial filtration efficiency can help minimize the risk of surgical site infections and promote faster wound healing.

2. Wound Dressings

Wound dressings play a crucial role in the healing process of various types of wounds. When selecting spunlace medical fabrics for wound dressings, healthcare facilities should consider the following factors:

-

Moisture Management: Wound dressings should effectively manage moisture levels to facilitate the healing process. Fabrics with good absorbency properties can help absorb excess wound exudate while maintaining a moist environment conducive to healing.

-

Non-Adherence: Wound dressings should not stick to the wound bed to avoid disrupting the healing process and causing pain during dressing changes. Fabrics with non-adherent properties can help prevent the dressing from adhering to the wound surface.

-

Comfort and Conformability: Wound dressings should be comfortable to wear and conform to the shape of the wound. Fabrics with soft textures and excellent drapeability can provide a comfortable and secure fit, ensuring optimal wound healing conditions.

By considering these specialized applications and their specific requirements, healthcare facilities can choose spunlace medical fabrics that ensure superior performance and meet the highest hygiene standards. Whether it is for surgical gowns or wound dressings, selecting the right fabrics is crucial in providing the best care possible to patients and creating a safe and sterile environment in healthcare settings.

Compliance with Regulatory Requirements

When it comes to selecting spunlace medical fabrics for specialized applications such as surgical gowns and wound dressings, healthcare facilities must ensure that the fabrics meet regulatory requirements to ensure superior performance and maintain high hygiene standards. Here are some important regulatory considerations to keep in mind:

1. FDA Approval

Healthcare facilities need to prioritize fabrics that have received approval from the U.S. Food and Drug Administration (FDA). The FDA sets strict guidelines for medical fabrics to ensure their safety and effectiveness. It is crucial to choose fabrics that comply with these regulations to minimize the risk of adverse reactions and ensure that the fabrics are suitable for use in healthcare settings.

2. ISO Standards

International Organization for Standardization (ISO) standards provide a globally recognized framework for quality management in various industries, including healthcare. When selecting spunlace medical fabrics, healthcare facilities should look for fabrics that comply with relevant ISO standards such as ISO 13485 (Medical devices - Quality management systems) and ISO 9001 (Quality management systems). Compliance with ISO standards ensures that the fabrics have been manufactured under strict quality control measures and adhere to the highest standards of performance and hygiene.

By prioritizing fabrics that have FDA approval and comply with ISO standards, healthcare facilities can ensure that the spunlace medical fabrics they choose are safe, reliable, and meet the necessary regulatory requirements. This not only helps protect the health and safety of both healthcare professionals and patients but also contributes to creating a sterile and hygienic environment in healthcare settings.

3. Material Composition and Testing

In addition to regulatory compliance, healthcare facilities should consider the material composition of the spunlace medical fabrics. Fabrics should be made from high-quality, hypoallergenic materials that are suitable for direct contact with the skin. It is also important to ensure that the fabrics undergo rigorous testing for factors such as fluid resistance, breathability, barrier effectiveness, absorbency, and non-adherence.

By carefully considering these factors and selecting spunlace medical fabrics that comply with regulatory requirements and meet specific application needs, healthcare facilities can ensure superior performance, promote optimal wound healing conditions, and maintain high hygiene standards. Choosing the right fabrics is vital in providing the best care possible to patients and creating a safe and sterile environment in healthcare settings.

Selecting the Right Supplier

When it comes to choosing spunlace medical fabrics for specialized applications such as surgical gowns and wound dressings, healthcare facilities must ensure that they select the right supplier. The supplier plays a crucial role in ensuring the superior performance and hygiene standards of the fabrics. Here are some key factors to consider when selecting a supplier:

1. Quality Assurance

The first and foremost consideration when choosing a supplier is their commitment to quality assurance. Look for suppliers who have established quality management systems in place and adhere to industry standards. A reputable supplier will provide certifications and documentation to demonstrate their compliance with regulatory requirements such as FDA approval and ISO standards. They should also have a transparent and traceable supply chain, ensuring the quality and integrity of the fabrics from raw materials to finished products.

2. Customization Options

Every healthcare facility has unique requirements for spunlace medical fabrics. The supplier should be able to offer customization options to meet these specific needs. This could include options for fabric weight, thickness, composition, and design. Customization ensures that the fabrics are tailored to the application, providing optimal performance and comfort for healthcare professionals and patients. A supplier that is willing to work closely with you to understand your requirements and provide customized solutions is a valuable partner in ensuring superior performance and hygiene standards.

3. Reliability and Timely Delivery

Reliability is another important factor to consider when selecting a supplier. Look for suppliers who have a proven track record of delivering high-quality products consistently. They should have a robust quality control process in place to ensure that each batch of fabrics meets the required standards. Additionally, timely delivery is crucial to ensure that healthcare facilities have a constant supply of fabrics to meet their needs. A reliable supplier will have efficient production and logistics systems in place to ensure on-time delivery.

By considering these factors when selecting a supplier for spunlace medical fabrics, healthcare facilities can ensure that they have a trusted partner who can provide superior performance and maintain high hygiene standards. The right supplier will not only deliver high-quality fabrics but also offer customization options and reliable service, contributing to the overall success of healthcare operations.

Conclusion

When it comes to selecting spunlace medical fabrics for specialized applications such as surgical gowns and wound dressings, healthcare facilities must make informed decisions to ensure superior performance and hygiene standards. The right supplier plays a crucial role in this process. By considering factors such as quality assurance, customization options, and reliability, healthcare facilities can ensure that they have a trusted partner who can provide high-quality fabrics that meet their unique requirements.

Making informed decisions for superior performance and hygiene standards

-

Quality Assurance: The first and foremost consideration when choosing a supplier is their commitment to quality assurance. Look for suppliers who have established quality management systems and adhere to industry standards. They should provide certifications and documentation to demonstrate their compliance with regulatory requirements such as FDA approval and ISO standards. A transparent and traceable supply chain is also important to ensure the quality and integrity of the fabrics.

-

Customization Options: Healthcare facilities have unique requirements for spunlace medical fabrics. The supplier should offer customization options to meet these specific needs. This includes options for fabric weight, thickness, composition, and design. Customization ensures that the fabrics are tailored to the application, providing optimal performance and comfort for healthcare professionals and patients. A supplier that is willing to work closely with you to understand your requirements and provide customized solutions is valuable in maintaining superior performance and hygiene standards.

-

Reliability and Timely Delivery: Reliability is crucial when selecting a supplier. Look for a supplier with a proven track record of consistently delivering high-quality products. They should have a robust quality control process in place to ensure that each batch of fabrics meets the required standards. Timely delivery is also important to ensure a constant supply of fabrics for healthcare facilities. A reliable supplier will have efficient production and logistics systems to ensure on-time delivery.

By considering these factors, healthcare facilities can make informed decisions when selecting a supplier for spunlace medical fabrics. A trusted partner will not only deliver high-quality fabrics but also offer customization options and reliable service, contributing to the overall success of healthcare operations. Ensuring superior performance and hygiene standards is essential in providing the best care for patients and maintaining the reputation of healthcare facilities.